The impact of increasing global gas and electricity prices has already plunged hundreds of thousands more UK families into fuel poverty.

Estimates suggest the current average fuel poverty gap of £233 per home* could more than double in the coming year. As a result, fuel poverty has arguably never been higher on the agenda for registered providers.

Unfortunately residents connected to communal heat networks will not be immune, as their monthly (and pre-payment) heat bills are typically tied directly to gas prices.

So, faced with an almost perfect storm; and against a backdrop of traditionally poorly performing communal heat networks – how can the performance of existing installations be improved to both urgently reduce tenant energy costs and prepare them for the transition to low carbon heat?

Optimisation is the answer

The under-performance of many residential communal heating installations has been well documented, indeed demonstrator projects like the Government’s Heat Network Efficiency Scheme (HNES) are already supporting performance uplifts to existing heat network or communal heating projects where outcomes for customers and operators are sub-optimal.

All too often communal heating schemes have “baked in” performance-gap issues, not least due to:

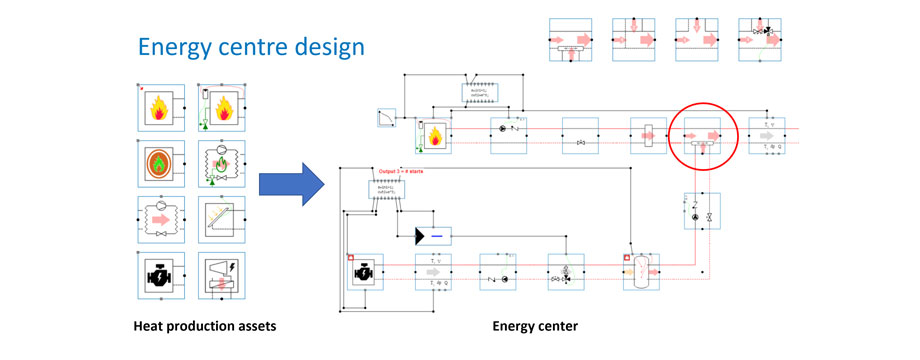

• Issues with initial design (over-sizing of plant/equipment and inappropriate hydraulic system design);

• Issues with incorrect component selection;

• Value engineering;

• Issues with incorrect commissioning;

From a technical point of view, the issues caused by these problems typically manifest themselves in the form of high return temperatures; and in the case of systems with multiple heat sources (often gas boilers with CHP or heat pumps), poor contribution to the heat demand from the energy efficient or low carbon heat sources – meaning the gas boilers do all the work.

Which in turn leads to systems that:

• Cost too much to run;

• Cost too much to install;

• Don’t deliver expected carbon savings;

• Fail to deliver adequate thermal comfort

20-40% energy savings

In fact optimisation of existing installations typically results in energy cost reductions of 20-40% by ensuring that areas of the installation that are the root cause of poor performance (typically fundamental hydraulic system errors; unoptimized control strategy; and poorly integrated plant) are removed. Impacts typically include significant reduction in return temperatures; and the ability to operate the entire installation at lower flow temperatures. All of which have the added benefit of lower heat losses and hence further system efficiency improvements.

Furthermore, these optimisations lend themselves perfectly to future-proofing existing installations for upgrade to low carbon heat sources later on – either replacement of fossil fuels with heat pumps; or connection to a wider district heat network.

© Hysopt www.hysopt.com

Hydraulic system digital twins

Such system optimisations become much more feasible with the assistance of digital technology. For example “hydraulic system digital twins” software, such as Hysopt.

Digital twin software allows engineers to build a virtual digital replica of the as-built installation. This enables building operators to gain a much clearer understanding of how systems actually perform in real life and how they can be optimised to perform more efficiently. This can answer questions such as:

• why existing installations are not performing as well as expected from an energy cost, carbon emissions, or thermal comfort point of view; or

• how the deployment of new low carbon heating and cooling technologies might be designed for optimal trade-off between operational cost; best-value upfront investment cost; or lowest carbon emissions.

They can also be instrumental in assisting asset management teams understand which buildings across their stock are likely to be easiest to tackle for low carbon heat upgrades, versus which will require more extensive “whole building” overhauls.

A good example of this is using a digital twin to calculate the impact of optimisation measures for the purposes of re-assessing building SAP/EPC ratings. Often hydraulic improvements can identify sufficient savings to move a building up one or even two SAP rating levels, benefits which can negate the expense (and risk) of external cladding, for example.

*BEIS Annual Fuel Poverty Statistics Report 2022

www.synergi.org.uk, info@synergi.org.uk, 03301 334 375

- Log in to post comments