Since the publication of Dame Judith Hackitt’s report for Government following the independent Review of Building Regulations and Fire Safety, much has been written about the risks of combustible insulation and cladding within our housing stock.

A number of HAs and local authorities have undertaken an exercise to identify social sector residential buildings clad with Aluminium Composite Material (ACM) panels and /or plastic insulation materials and / or any defective fire stopping. According to the Health & Safety Executive (HSE)*, “these buildings are most likely to need to have removal and replacement works undertaken”.

Recent guidance issued by the Ministry of Housing Communities & Local Government (MHCLG)** makes it clear that “Local Authorities have powers, under the Housing Act 2004, to calculate the seriousness of certain hazards and take enforcement action against building owners or landlords based on their assessment.” MHCLG has announced a number of measures to make sure that local authorities have the confidence to use these powers to take enforcement action for high rise residential buildings with unsafe ACM cladding. This would begin with a “Housing Health and Safety Rating System (HHSRS) assessment to ascertain the risk of harm to an occupier that the cladding process”.

In evaluating the existing risks and, then, taking the right replacement and remedial actions, it is vitally important for HAs and their contractors to understand the different product distinctions, performance characteristics and application benefits as they follow the HSE guidance. In particular, the significant differences between Reaction to Fire and Fire Resistance.

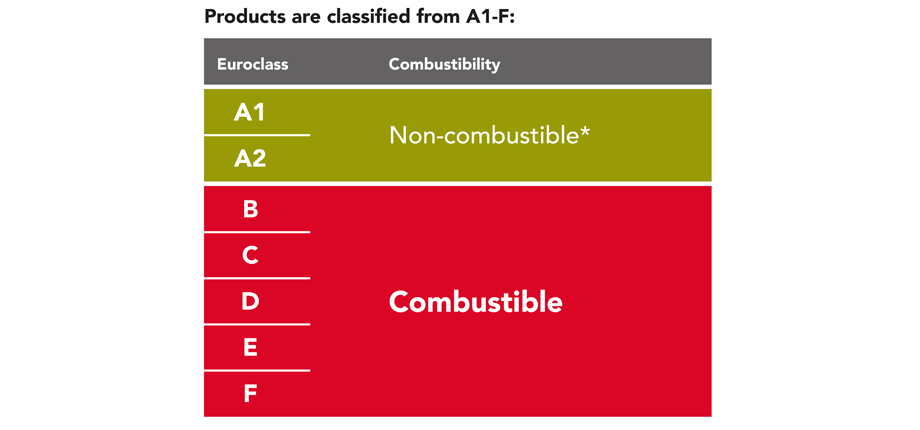

Firstly, considering reaction to fire, there is the distinction between what is combustible and what is non-combustible. Here, we should recognise the classifications given within the Euroclass system applicable under CE Marking rules.

The Euroclass system classifies the reaction to fire performance of building products in accordance with BS EN 13501-1 and requires products to undergo testing for a range of characteristics including: ignitability, flame spread, heat release, smoke production and propensity for producing flaming droplets/particles. The Euroclass system is accepted in the UK and by all European Union States (and is mandatory where there is a Harmonised Product Standard). It includes seven classification levels, A1, A2, B, C, D, E and F, plus one rating (NPD), that sits alongside but outside these ratings. A1 is the highest performance level and F the lowest. Products classified A1 or A2 are considered non-combustible* and those classified B, C, D, E or F combustible.

*A1 and A2 classified products are tested in accordance with the non-combustibility test EN ISO 1182 to identify that they will not, or significantly not, contribute to a fire. Furthermore, A1 classified products are defined as ‘non-combustible’ in official government guidance to Building Regulations in all regions of the UK and in the Republic of Ireland, with both A1 and A2 products defined as non-combustible in Scotland.

Manufacturers of CE-marked construction products in the UK are legally obligated to declare an RtF rating, meaning that HAs can find out the combustibility rating of cladding and insulation products from the products’ Declaration of Performance (DoP) certificates.

The term Class 0 is not to be confused with a Euroclass reaction to fire rating. Class 0 only assesses ‘spread of flame’, as opposed to the ‘reaction to fire’ assessment of materials which are made through the Euroclass system, but having Class 0 certification is commonly misinterpreted to mean that a product is non-combustible or a close equivalent. It is not uncommon for combustible materials manufacturers to provide a Class 0 rating in lieu of a Euroclass rating and to focus their product marketing around it.

Furthermore, marketing terms such as fire safe, fire proof, fire retardant or flame proof are frequently used by some manufacturers to describe the reaction to fire properties of products which are classified as combustible.

ROCKWOOL believes that the best way to help ensure optimum fire protection and tenant safety is, firstly, to follow the HSE guidance in dealing with the key fire risks during the removal and replacement of insulation and cladding. Secondly, replace the cladding and insulation with A1 and A2 cladding and insulation materials, supported by the testing and classification to EN 13501-1.

We believe that to truly ensure both public safety and building resilience, only Euroclass certified A1 and A2 materials should be used on buildings above 11m.

ROCKWOOL provides practical insight and knowledge of product performance and fire safety in its recently launched ABC (A-Rated Products, Building Envelope and Compartmentation) CPD Programme. The key learnings from the CPD programme are applicable to the main areas of the building envelope, specifically facades and roofs, in addition to highlighting the importance of compartmentation to prevent fire spread. The CPD programme, comprising three modules, aims to develop a practical understanding, to support HAs and construction professionals involved in building design and renovation.

For more information on the ABC CPDs, visit www.rockwool.co.uk/learning/cpds/cpd-abc. Details on the full range of A1 and A2 ROCKWOOL and Rockpanel stone wool based solutions available for insulation and cladding applications in the social housing sector can be found at www.rockwool.co.uk and www.rockpanel.co.uk.

* HSE Managing Fire Risk During Cladding and Insulation Removal and Replacement on Tall Buildings, October 2018 www.hse.gov.uk/foi/internalops/og/og-00106.pdf

** MHCLG Local Authority Enforcement Powers under the Housing Act 2004, 21 February 2019 www.gov.uk/government/publications/local-authority-enforcement-powers-under-the-housing-act-2004?utm_source=4cd8c1f7-661d-47e4-950d-c7079daf7029&utm_medium=email&utm_campaign=govuk-notifications&utm_content=immediate

- Log in to post comments