Standing seam cladding systems offer distinct advantages over traditional rainscreen solutions like cassette and rivet fix systems, particularly in terms of performance, aesthetics, and long-term durability. One of the key benefits is their ability to accommodate thermal movement. Thanks to the use of fixed and sliding clips, metal panels in standing seam systems can expand and contract naturally, reducing structural stress and preventing issues such as buckling or cracking over time.

In comparison, cassette systems often rely on rigid fixings that restrict movement, which can lead to misalignment and accelerated wear. Rivet fix systems, while easier to install, offer limited flexibility and are prone to fastener loosening or corrosion over time. Visually, standing seam cladding delivers a sleek, contemporary look with concealed fixings and uninterrupted lines—enhancing both architectural appeal and weather resistance. The interlocking seams are highly effective at preventing water ingress, making the system ideal for exposed environments.

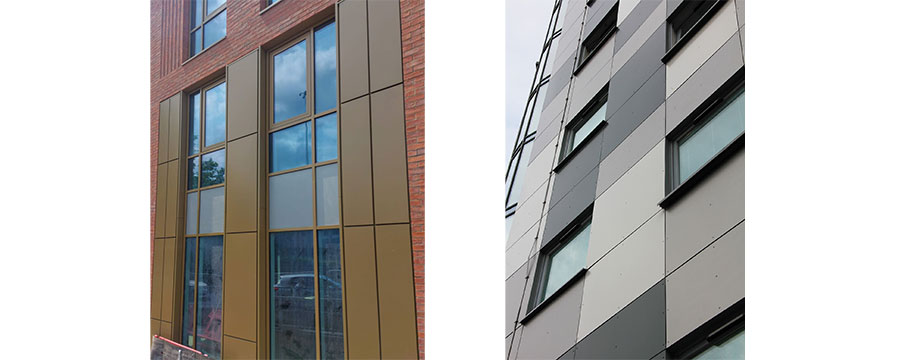

Left: Cassette Panels, Right: Rivet Fix Panels

While cassette systems can appear clean, their pronounced panel joints may disrupt the visual flow. Rivet fix systems, with exposed fasteners, tend to convey a more industrial aesthetic that may not suit modern design goals. Fire safety is another area where standing seam systems excel. Their minimal cavity space and concealed fixings reduce airflow behind the panels, limiting the chimney effect that can accelerate fire spread. This contrasts with cassette systems, which may inadvertently create airflow pathways—as highlighted in the analysis of the Grenfell Tower fire.

Overall, standing seam cladding combines durability, design flexibility, and enhanced safety, making it a superior choice for contemporary construction projects.

Fabrication services from Valcan

Valcan offers a full suite of fabrication services, tailored to meet everything from standard fixing requirements to bespoke system designs. One of our most popular solutions is the Standing Seam Effect system, widely used across cladding projects.

This system features either our VitraDual or Solid Safe A1 Aluminium panels, which can be fabricated vertically or horizontally. Each panel includes a raised seam that runs the length of the strip and overlaps the adjacent panel, creating a sleek, continuous finish. Panels are securely fixed to the building using our VitraFix VF1 system.

Standing Seam Panels

The Standing Seam Effect system offers a host of practical advantages. It’s cost-effective, straightforward to install, and helps streamline logistics throughout the project. The panels are classified in accordance with BS EN 13501-1, ensuring the best safety performance. Lightweight and with a fully warranty, they require no specialist tooling beyond a standard cladding kit, making installation and maintenance hassle-free. In the event of damage, individual sections can be easily replaced without affecting the surrounding panels. Widths and lengths of the panels can be customised to suit your project, within the limits of our standard raw sheet sizes.

We understand that every project is unique and may require custom solutions. Our dedicated team is ready to work closely with you to design bespoke cladding systems tailored to your specific needs. From precision fabrication to a diverse range of custom colours and finishes, we provide comprehensive installation support to ensure your vision becomes a reality.

Visit https://valcan.co.uk/fabrication-services/ for more information or to discuss your projects with the fabrication team at Valcan.

Images © Valcan

- Log in to post comments